What is a Forklift? Types, Uses, Operator Training, & Certification

Forklifts are a crucial part of modern industries, yet many people don’t fully understand their significance. From warehouses to construction sites, forklifts are used for heavy lifting, but improper use can lead to costly accidents and inefficiencies. The lack of knowledge about the types, usage, and maintenance of forklifts can create major challenges for both operators and businesses.

The solution lies in understanding what a forklift is and how it functions effectively in various environments. With proper training, certification, and awareness of safety standards, businesses can minimize risks and optimize forklift operations. In this guide, we’ll explore what is a forklift, its types, uses, and the importance of proper handling, ensuring you’re equipped with the knowledge to work safely and efficiently.

What is a Forklift?

A forklift is a powered industrial truck designed to lift and move heavy materials over short distances. These machines are commonly used in warehouses, construction sites, and factories to transport goods such as pallets and boxes. Forklifts are powered either by electric motors or internal combustion engines (such as diesel or propane). The forks of the forklift slide under the load to lift and carry it, while the mast controls the lifting and lowering of materials.

Different types of forklifts are designed for various uses. For example, reach trucks are used in narrow aisles, while counterbalance forklifts offer a stable design to handle heavier loads. Forklifts can also be equipped with specialized attachments like clamps, rotating forks, and hydraulic jacks, making them versatile tools for handling diverse materials in a wide range of industries.

History of the Forklift

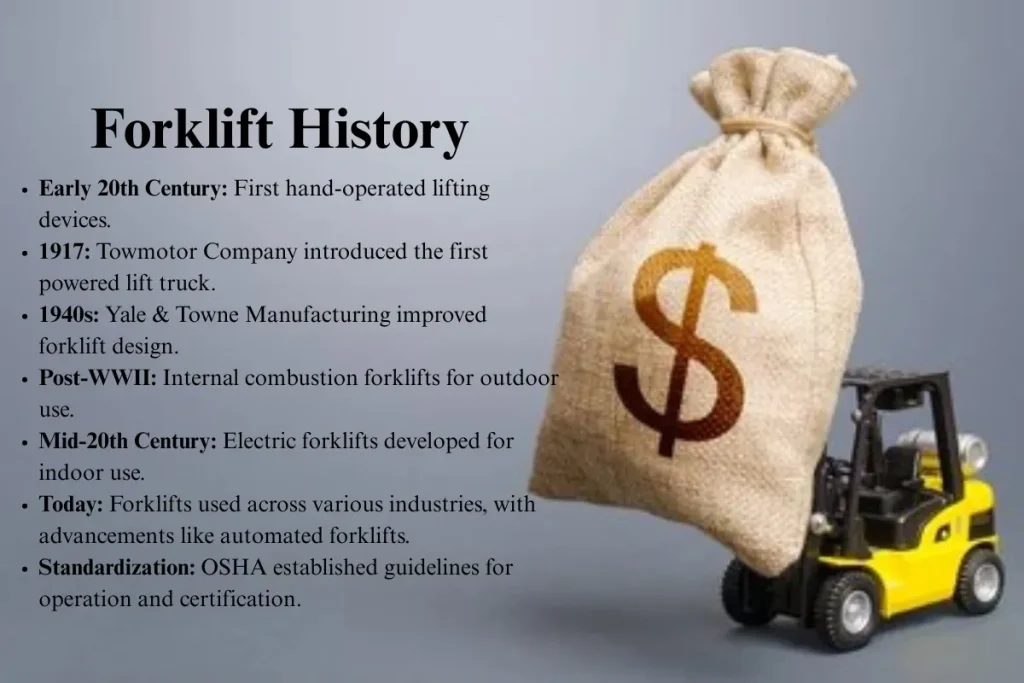

The forklift has an interesting history, evolving from basic lifting equipment into the versatile machine we use today. The first forklifts were introduced in the early 20th century, with a major leap occurring during World War I. The initial designs were simple, hand-operated lifting devices that could carry heavy loads. However, as industries grew and material handling demands increased, these devices were upgraded to powered machines.

In 1917, the Towmotor Company produced the first powered lift truck, marking the beginning of forklift development. In the following decades, companies like Yale & Towne Manufacturing played a pivotal role in refining forklift design, focusing on making the machines more efficient and easier to operate. The introduction of internal combustion forklifts powered by diesel and propane allowed forklifts to operate in outdoor environments, where they could handle heavy loads on construction sites and rough terrains.

The development of electric forklifts came in the mid-20th century, providing a quieter and more environmentally friendly alternative for indoor use. Over time, forklifts became essential in industries beyond warehousing, such as construction and logistics. Companies now use forklifts for tasks such as unloading trucks, pallet removal, and material handling. Today, we see advancements such as automated forklifts that are increasingly used in modern warehouses, making forklift operations even more efficient.

As forklifts became integral to business operations, their design and operation were standardized and regulated to ensure safety. The OSHA (Occupational Safety and Health Administration) set specific guidelines for forklift operation and certification, requiring operators to undergo proper training. This standardization has played a key role in minimizing accidents and improving workplace safety.

In summary, the forklift’s history is marked by continuous innovation, leading to the advanced, diverse forklifts we use today. With proper training and certification, forklifts help businesses increase productivity while ensuring safety in a variety of industries, including construction, warehousing, and material handling.

Key Components of a Forklift

Forklifts are composed of several key parts that work together to enable the lifting and transportation of heavy loads. Each component plays a critical role in the operation, and understanding these parts is essential for proper forklift use and maintenance.

Overview of Essential Parts

At the heart of every forklift are a few primary components: the mast, forks, carriage, wheels, and the power source. The mast is the vertical component that allows the forklift to lift and lower loads. It is made up of several sections that slide within each other, enabling the forks to reach various heights. The forks are the flat, horizontal prongs that slide under the load to lift and carry it. They are usually adjustable to accommodate different sizes of loads.

The carriage is the part that holds the forks and allows them to move up and down the mast. This part is essential for stabilizing the load during the lifting process. The wheels of a forklift are designed to carry the entire weight of the machine and its load. Forklifts typically have pneumatic tires for outdoor use, while cushion tires are commonly used indoors for smoother operations.

Mast, Forks, Carriage, Wheels, and Power Source

Each forklift is powered by either electric motors or internal combustion engines (diesel, propane, or gasoline). Electric forklifts are known for their quiet operation and zero emissions, making them ideal for indoor use. On the other hand, diesel and propane forklifts are designed for outdoor applications, where greater power is needed to handle rough terrain and heavy loads. The power source drives the hydraulic system, which controls the lifting and lowering of the mast.

The hydraulic system is what makes the forklift’s lifting capability possible. It consists of cylinders, valves, and fluid lines that work together to lift heavy loads. The forklift’s hydraulic fluid is pressurized to generate the force needed to raise and lower the mast, allowing the forks to transport materials efficiently. The control system, typically controlled by the operator via a steering wheel, pedals, and levers, allows the user to move the forklift, control the lift, and perform various other tasks like turning and shifting.

How These Components Work Together for Lifting and Transportation

When an operator uses the forklift, they control the power source, which drives the hydraulic system. The hydraulic pressure lifts the mast, raising the forks under the load. The carriage stabilizes the forks, ensuring that the load is lifted evenly. As the load is raised, the operator can move the forklift using the control system to navigate the workspace. The wheels allow the forklift to move forward, backward, or even turn in tight spaces. The combination of these components enables the forklift to perform essential tasks like unloading trucks, pallet handling, and transporting materials.

Overall, these components work seamlessly together to ensure that the forklift operates smoothly, efficiently, and safely. Regular maintenance of these parts is crucial to prevent breakdowns and to ensure optimal performance.

A forklift’s cooling system, which often includes a radiator, plays a crucial role in preventing overheating during extended operations. Understanding how the radiator functions can help forklift operators and maintenance teams ensure the equipment runs smoothly.

How Do Forklifts Work?

Forklifts are specialized vehicles designed to lift, carry, and move heavy loads in warehouses, construction sites, factories, and various other settings. Understanding the basic working principles of forklifts is essential for operators to safely and effectively use these machines. Below, we break down how forklifts work, covering their power systems, lifting mechanisms, and control systems.

The Basic Working Principles of Forklifts

At their core, forklifts operate by using hydraulic power to lift heavy loads. The system that powers the forklift mast (the vertical lifting component) involves hydraulic fluid that moves through cylinders, allowing the forks to raise and lower with precision. When the operator activates the lift, the hydraulic pump pressurizes the fluid, moving it through valves to the mast cylinders. This pressurization causes the mast to rise and fall, lifting or lowering the load.

The forks of the forklift are positioned at the front of the machine and are specifically designed to slide under pallets or other materials for transport. The load is secured onto the forks by lifting it off the ground, and the forklift then uses its propulsion system to transport the load to the desired location.

How Forklifts Are Powered (Electric vs. Internal Combustion)

Forklifts can be powered in two main ways: through electric motors or internal combustion engines (ICE). Each power system has its advantages depending on the environment and the nature of the tasks at hand.

- Electric Forklifts: These are powered by rechargeable batteries. Electric forklifts are highly efficient, producing no emissions, which makes them ideal for indoor operations, such as in warehouses and distribution centers. They offer quieter operations and are easier to maintain than internal combustion forklifts. However, they may not have the same power and load capacity as their gas-powered counterparts.

- Internal Combustion Forklifts: These forklifts run on gasoline, diesel, or propane engines. Internal combustion forklifts provide more power and are better suited for outdoor operations where high lifting capacities and rough terrain handling are required. However, they produce emissions and are generally noisier than electric models. They also require more maintenance due to the complexity of their engine systems.

Many modern forklifts, especially those in large warehouses, utilize advanced wireless systems for communication. The difference between Cat5 and Cat6 cables can affect the speed and reliability of these wireless systems, influencing operational efficiency.

The Lifting Mechanism and Its Operation

The lifting mechanism of a forklift is powered by a hydraulic system, which is responsible for raising and lowering the mast and forks. The system consists of various hydraulic cylinders, a pump, and valves. When the operator activates the lift control, it sends hydraulic fluid through the system, causing the cylinders to extend and lift the mast.

The mast is composed of several sections that slide inside one another. The sections are designed to handle the weight of the load and allow the forklift to lift pallets to different heights, depending on the forklift’s capacity. Forklifts with telescopic or multi-stage masts can extend to reach very high storage racks or elevated workspaces, while other forklifts are better suited for lifting lower loads.

Forklift Propulsion and Control Systems

The propulsion system of a forklift is what moves the machine forward or backward. For electric forklifts like turret forklifts, the motor is powered by the battery, while for internal combustion forklifts, the engine provides the power. The propulsion system works in tandem with the forklift’s drive system, which includes the wheels and axles that allow movement in different directions.

Forklifts are equipped with a control system that allows the operator to manage various functions. This system typically includes:

- Steering: Forklifts can be steered using a traditional steering wheel, joystick, or tiller (depending on the model). The steering system allows the operator to maneuver the forklift in tight spaces, especially when working in narrow aisles.

- Pedals and Levers: Like traditional vehicles, forklifts have pedals for controlling speed and stopping (similar to a car’s accelerator and brake). Levers are used for controlling the lift, tilt, and direction of the mast.

- Safety Features: Modern forklifts come with numerous safety systems such as overhead guards, seat belts, and speed controls to protect operators and other workers from accidents.

Forklifts with advanced control systems often rely on sophisticated wiring, such as fiber optics, to ensure precise communication between sensors and controllers.

Types of Forklifts

There are several types of forklifts designed for different applications. Each forklift type is built with specific features to suit its purpose, whether it’s for indoor use, rough terrain, or handling heavy loads. Below is an overview of the most common forklift types and their unique capabilities.

1. Counterbalance Forklifts

One of the most commonly used forklifts, counterbalance forklifts are designed with a counterweight at the rear of the vehicle to balance the weight of the load being lifted. These forklifts are highly versatile and are commonly used in warehouses and factories. They are equipped with either electric or internal combustion engines, making them suitable for both indoor and outdoor operations. Counterbalance forklifts are ideal for lifting and stacking materials in tight spaces.

2. Reach Trucks

Reach trucks are specifically designed for narrow aisle operations in warehouses. These forklifts have an extended mast and can lift pallets to great heights while still allowing the operator to maneuver in tight spaces. Reach trucks are commonly used for high-lift applications and are particularly efficient in warehouses with vertical storage systems. They are usually powered by electric motors, making them suitable for indoor environments.

3. Pallet Jacks (Pallet Trucks)

Pallet jacks, also known as pallet trucks or hand pallet jacks, are small manual forklifts used for moving palletized loads over short distances. These trucks are typically used in warehouses and supermarkets for simple tasks like moving goods from one shelf to another. Electric pallet jacks are also available, offering a powered option for heavier loads. Pallet jacks are highly efficient for moving goods on flat surfaces and are often used in combination with pallet racking systems.

4. Order Pickers

Order pickers are forklifts designed to help workers pick items from shelves or racks in warehouses. They are unique in that the operator’s platform elevates along with the forks to allow the operator to retrieve items from heights. Order pickers are used in distribution centers for fast, precise picking. Operators can access high shelves, and these forklifts are ideal for smaller, lighter loads. Electric order pickers are commonly used in indoor environments for order picking tasks.

5. Rough Terrain Forklifts

Rough terrain forklifts are designed for outdoor use in construction and rugged environments. They are equipped with large tires and 4-wheel drive capabilities to handle uneven surfaces and rough terrains. These forklifts are typically used for lifting heavy materials on construction sites or farms. The heavy-duty forks and high lifting capacity make them suitable for lifting large containers, pallets, and other large loads in construction and logistics industries.

6. Telehandlers (Telescopic Forklifts)

Telehandlers, also known as telescopic forklifts, are versatile machines used for lifting and placing materials at heights. They combine the functions of a forklift and a crane, with an extendable boom that can reach great heights. Telehandlers are widely used in construction sites, agriculture, and material handling. They are equipped with attachments like forks, buckets, or lifting hooks for different tasks, making them highly adaptable for various lifting and loading jobs.

7. Side Loaders

Side loaders are forklifts that lifted trucks and transport loads from the side, rather than from the front. They are commonly used for long loads that need to be transported sideways, such as pipes, timber, and lumber. These forklifts are highly useful in warehouse and storage settings where long, bulky materials are stored. Side loaders are also available in both electric and combustion engine models, depending on the application.

8. Walkie Stackers

Walkie stackers are small forklifts that are designed to be operated by a person walking behind them. They are typically used in small warehouses or retail environments for lifting and stacking pallets at lower heights. These machines are compact and easy to maneuver, making them ideal for tight spaces. Electric walkie stackers are commonly used for lifting lighter loads and are great for order picking tasks.

9. Automated Forklifts

Automated forklifts are the future of material handling. These robotic forklifts are designed to operate autonomously in warehouses, using sensors and AI to navigate and lift materials. They are commonly used in highly automated warehouses where efficiency and speed are paramount. Automated forklifts help reduce human labor and increase productivity, offering an efficient, safe, and cost-effective alternative for material handling tasks.

Specialized Forklifts

In addition to the commonly used forklifts, there are various specialized forklifts designed for specific industries and applications. These forklifts cater to unique needs, including transportation, safety, and efficiency in environments where standard forklifts might not suffice. Let’s explore some of the most commonly used specialized forklifts, their features, and how they are revolutionizing their respective industries.

Truck-Mounted Forklifts

Truck-mounted forklifts are a unique type of fork lift designed for on-site transport and loading/unloading operations. These forklifts are mounted on the back of a truck, making them highly practical for transporting goods over long distances. They are particularly useful in industries where material handling is needed on the move, such as construction, lumber yards, and delivery services.

The key advantage of a truck-mounted forklift is its ability to load and unload directly from the truck, eliminating the need for a separate material handling system. Operators can transport the forklift to the site and immediately begin unloading without waiting for additional equipment. This transportability significantly reduces downtime and increases overall productivity.

While truck-mounted forklifts offer excellent versatility in terms of mobility, they also require careful driving and parking to ensure that they are safely secured on the truck bed. Additionally, their hydraulic system needs to be optimized to handle the weight and type of loads being transported.

Marina Forklifts

Marina forklifts are specialized forklifts designed to operate in harbors and docks. These forklifts are often used in the maritime industry to load and unload boats and yachts from trailers, containers, or piers. Their unique design includes water-resistant components to withstand the harsh conditions of marine environments, such as saltwater exposure and moisture.

Marina forklifts are capable of handling large and heavy loads typically found in boat transportation, offering the ability to move boats of various sizes and weights. These forklifts feature wider wheels or tires to support large, heavy loads and prevent the forklift from sinking into soft ground or mud typically found in marinas.

Additionally, marina forklifts come with specialized attachments like boat cradles and fork extensions to handle boats of different sizes and shapes. They are also built with height-adjustable masts to ensure easy handling of boats on trailers or platforms.

Explosion-Proof Forklifts

In environments where hazardous materials are present, the use of explosion-proof forklifts is essential. These forklifts are specifically designed to operate safely in explosive atmospheres, such as those found in chemical plants, oil refineries, or areas where flammable gases or dust are common.

Explosion-proof forklifts are equipped with a variety of safety features to prevent sparks or heat generation, which could lead to dangerous explosions. These features include:

- Non-sparking components: Parts like motors, wires, and electrical components are made from materials that do not generate sparks under normal operational conditions.

- Sealed and enclosed electrical systems: To prevent any possibility of ignition, these forklifts have sealed enclosures for electrical systems that minimize exposure to hazardous environments.

- Specialized tires: Explosion-proof forklifts are fitted with static dissipative tires that prevent the buildup of static electricity, which could trigger an explosion in sensitive areas.

These forklifts are required to meet stringent safety standards (such as UL 583 or ATEX certifications) and are often used in industries dealing with volatile substances where the smallest spark can have catastrophic consequences.

Automated Forklift Trucks

The rise of automation is significantly shaping the future of forklift use in warehouses, distribution centers, and manufacturing facilities. Automated forklift trucks (also known as AGVs – Automated Guided Vehicles) are forklifts that operate without human intervention. These forklifts use sensors, cameras, and navigation systems to carry out tasks such as picking up, transporting, and delivering loads within a facility.

The key benefits of automated forklift trucks include:

- Increased Efficiency: These forklifts can work 24/7, without the need for breaks, rest periods, or shift changes. This increases warehouse productivity and helps meet high demands.

- Enhanced Safety: By eliminating human operators from the vehicle, the risk of operator-related accidents is greatly reduced. Automated forklifts are equipped with advanced safety features, such as collision detection and automated braking systems.

- Cost Savings: Over time, the use of automated forklifts can lead to significant cost savings by reducing labor costs and increasing throughput. These forklifts also reduce the likelihood of costly mistakes or accidents, which can lead to damaged goods or equipment.

Automated forklift systems are typically integrated with warehouse management systems (WMS), allowing them to receive real-time instructions on where to pick up and drop off materials, optimizing the entire workflow.

Forklift Safety and Legislation

Ensuring forklift safety is crucial to maintaining a productive, hazard-free workplace. Forklifts are powerful machines, and without proper safety protocols, they can lead to significant accidents and injuries. This section delves into safety protocols, regulations, and the organizations that work to ensure the safe operation of forklifts in various industries.

Safety Protocols and Hazards

Operating a forklift involves several risks and potential hazards. Forklifts, due to their size, weight, and speed, pose threats to operators, pedestrians, and others in the vicinity. Here are some of the most common forklift accidents and the safety features in modern forklifts designed to mitigate these risks:

Potential Risks and Common Forklift Accidents:

What are the main causes of injuries when using forklifts?

- Collisions: Forklifts are involved in a significant percentage of warehouse accidents. They can collide with other equipment, walls, or pedestrians, especially in narrow aisles or high-traffic areas.

- Tip-over accidents: A forklift can tip over if an operator improperly handles the load, causes a shift in weight distribution, or drives too fast while turning.

- Pedestrian Injuries: Forklift operators can unintentionally hit pedestrians, leading to serious injuries or fatalities. Pedestrians are often not aware of the blind spots around forklifts, making safety awareness crucial.

- Forklift-Related Crashes: Forklift operators sometimes crash into other vehicles, walls, or storage racks, particularly in crowded environments.

- Falling Loads: If a load is not properly secured, it can fall off the forks, causing injuries or damaging other items.

Key Safety Features of Modern Forklifts: To reduce the risks mentioned above, modern forklifts come with various safety features:

- Safety lights and horns: Forklifts are often equipped with warning lights and horns that alert pedestrians and other workers to the presence of a moving forklift.

- Anti-rollover protection: Most forklifts now come with rollover protection systems (ROPS), which prevent or minimize the damage caused if the forklift tips over.

- Load weight sensors: Many forklifts are equipped with sensors that alert operators when the load exceeds the forklift’s weight limit, ensuring proper balance and preventing tipping.

- Automatic speed controls: Some models have automatic speed limiters, which help control the forklift’s speed, especially in tight or high-risk areas.

Regulations and Standards

OSHA Guidelines and Industry-Specific Legislation: Forklift operation and safety are regulated by several regulatory bodies, with OSHA (Occupational Safety and Health Administration) being the primary agency in the U.S.. OSHA guidelines ensure safe operation of forklifts by enforcing compliance with laws designed to prevent accidents, injuries, and fatalities.

Key regulations and standards that forklift operators must adhere to include:

- OSHA’s 29 CFR 1910.178: This regulation establishes the requirements for safe operation of powered industrial trucks (forklifts), covering aspects such as training, inspection, and maintenance.

- Forklift Certification and Training: OSHA mandates that operators receive formal forklift training and certification. This training ensures that operators understand the risks associated with operating forklifts and how to safely use them in various work environments. Certification is required for operators of electric forklifts, gas forklifts, and all other types of powered industrial trucks.

- Forklift Maintenance: OSHA guidelines require that forklifts undergo routine inspections and maintenance to ensure they are safe to operate. Forklift operators must perform pre-shift inspections to check for hazards such as malfunctioning parts, low fuel levels, or damaged tires.

- Safety Zones: Workplaces must establish safety zones or pedestrian walkways in areas where forklifts are in use to minimize the risks of collisions.

Forklift Training Requirements and Certifications: To be legally allowed to operate a forklift, operators must undergo formal forklift training and obtain a certification. The training should include:

- Classroom instruction: Operators must learn the safety guidelines, operating principles, and emergency protocols related to forklift use.

- Practical training: Trainees must practice driving a forklift in a controlled environment to ensure that they can handle the machine effectively and safely.

- Certification: How to get forklift certified? After completing the training, operators must pass both written and practical exams to demonstrate their competence in operating a forklift safely.

- Refresher courses: Operators are required to take refresher courses every three years or after any accidents or incidents to ensure their knowledge remains up-to-date.

Associations and Organizations

Several key organizations play a crucial role in setting safety standards for forklifts and material handling equipment, as well as supporting certification programs. These bodies provide guidelines, training programs, and resources to ensure a safe working environment.

- OSHA (Occupational Safety and Health Administration): As the regulatory body in the United States, OSHA sets the standards for forklift safety, training, and maintenance.

- ANSI (American National Standards Institute): ANSI is responsible for establishing the standards for powered industrial trucks and forklifts, ensuring they meet safety requirements in the workplace.

- ISO (International Organization for Standardization): ISO provides global standards for forklift manufacturing, design, and safety features, promoting international consistency in safety practices.

- NPTC (National Pallet Truck Certification): NPTC provides training, license, and certification programs for pallet truck lift operators, ensuring safety when handling forklifts in warehouses and storage facilities.

- NAFEM (North American Food Equipment Manufacturers Association): NAFEM promotes best practices for the use of forklifts in the foodservice industry and helps maintain high safety standards in equipment.

When considering the financial implications of acquiring or maintaining a forklift, especially for businesses in places like California, understanding tax responsibilities such as capital gains tax can be beneficial. Certain forklift sales or equipment purchases might affect your taxable income or capital gains.

How to Choose the Right Forklift

Selecting the right forklift is a crucial decision for ensuring smooth operations in warehouses, construction sites, and industrial settings. It’s essential to consider various factors such as fuel type, load capacity, and environmental conditions to make the best choice for your specific needs. This section will guide you through the process of selecting the appropriate forklift for your business.

Choosing Between Electric and Gas-powered Forklifts

One of the primary decisions you’ll need to make when selecting a forklift is whether to go for an electric forklift or a gas-powered forklift. Both types have their advantages and are suited for different working environments. Here’s a breakdown of their pros and cons:

Advantages of Electric Forklifts:

- Environmentally Friendly: Electric forklifts are a great choice for businesses aiming to reduce their carbon footprint. Since they don’t use fuel and rely on rechargeable batteries, they produce no emissions, making them ideal for indoor environments where air quality is a concern.

- Lower Operating Costs: While electric forklifts may have a higher upfront cost, they tend to have lower operating costs over time. Electric forklifts require less maintenance because they have fewer moving parts, and the cost of charging batteries is lower than the cost of refueling gas-powered machines.

- Quieter Operation: Electric forklifts are much quieter than their gas counterparts, making them better suited for quiet work environments like retail stores, warehouses, or hospitals where noise reduction is a priority.

- Efficiency in Tight Spaces: Many electric forklifts have compact designs, making them a great fit for narrow aisles and tight spaces commonly found in warehouses and retail environments.

When to Choose Internal Combustion (IC) Forklifts: Internal combustion (IC) forklifts, powered by gas or diesel, are ideal for specific work environments where electric models may not be suitable:

- Outdoor Operations: IC forklifts are more suitable for outdoor environments because they can handle rough terrain and adverse weather conditions better than electric forklifts.

- Heavy-Duty Tasks: For applications involving heavy lifting and intense workloads, gas-powered forklifts are preferred. IC forklifts tend to have a higher weight capacity and are more robust, which makes them ideal for construction sites or industrial areas where heavier loads need to be moved.

- Long Shifts: In environments where continuous operation is required, gas-powered forklifts are more suitable. Electric forklifts require periodic charging, while IC forklifts can operate for longer periods without refueling.

Factors to Consider When Renting or Buying a Forklift

When renting or buying a forklift, there are several key factors to consider to ensure that you select the right forklift for your specific needs. Each factor plays a crucial role in determining the type and size of forklift that will provide the best performance and safety in your operations.

Choosing the Right Forklift for Your Needs (Capacity, Environment, etc.):

- Load Capacity: It’s essential to choose a forklift with an appropriate load capacity for the materials you’ll be lifting. Overloading a forklift can lead to accidents or damage to the equipment. Always check the load center and lifting capacity of the forklift to ensure it matches your operational needs.

- Environment: Consider the operating environment before making your decision. Electric forklifts are ideal for indoor environments where there are concerns about emissions and noise. On the other hand, gas-powered forklifts are more suited for outdoor environments, such as construction sites and large warehouses.

- Floor Conditions: Rough terrain forklifts with pneumatic tires are suitable for outdoor environments with uneven surfaces. For smooth indoor surfaces, electric forklifts or manual pallet jacks are often better suited, as they provide smooth handling and precise control.

- Aisle Width: Narrow aisle forklifts are perfect for facilities with limited space. If your warehouse or storage area has narrow aisles, a narrow aisle reach truck, low trucks, or a walkie stacker may be a better option for maximizing storage space while maintaining safe and efficient forklift operation.

Forklift Sizes and Classifications: Forklifts come in various sizes and classifications to meet different operational requirements. The material handling equipment industry classifies forklifts into different types based on their design and intended usage. Here are the key forklift classifications:

- Class I: Electric Motor Rider Trucks: These electric forklifts are ideal for indoor applications and are commonly used in warehouses and retail settings.

- Class II: Electric Motor Narrow Aisle Trucks: These forklifts are designed for narrow aisles, making them ideal for high-density storage in warehouses.

- Class III: Electric Motor Hand Trucks: These walkie stackers or pallet jacks are commonly used for light material handling tasks in confined spaces.

- Class IV: Internal Combustion Engine Trucks: These gas-powered forklifts are used for general outdoor applications and can handle heavy loads.

- Class V: Internal Combustion Engine Trucks (Pneumatic Tires): These forklifts are ideal for rough terrain and heavy lifting tasks.

- Class VI: Electric and Internal Combustion Engine Trucks: This classification is used for hybrid models that combine both electric and gas-powered features.

- Class VII: Rough Terrain Forklifts: These forklifts are designed for outdoor use in rugged environments like construction sites, agricultural fields, and lumberyards.

When purchasing a forklift, consider not only the size of the machine but also its operation requirements and how it will perform in your specific environment. Consult with a forklift expert or dealer to ensure that you are selecting the correct forklift size and type for your operation.

Forklifts in Different Industries

Forklifts are versatile and indispensable in a variety of industries. Their ability to lift, move, and stack materials efficiently makes them essential equipment for improving productivity and ensuring smooth operations across diverse sectors. Let’s explore how forklifts are used in some of the most critical industries, including warehouses, construction, and manufacturing.

Forklifts in Warehouses and Distribution Centers

In warehouses and distribution centers, forklifts are crucial for maintaining an organized, efficient, and safe work environment. These facilities often handle large volumes of goods that need to be stored, retrieved, and shipped quickly.

Popular Forklift Types Used in Warehouses:

- Reach Trucks: These narrow aisle forklifts are designed to operate in tight spaces. Reach trucks can extend their forks to lift materials to great heights, making them perfect for high-density racking systems in warehouses.

- Pallet Jacks (Manual and Electric): Manual pallet jacks are used for light material handling tasks in tight spaces, while electric pallet jacks are ideal for heavier tasks and require less physical effort from operators.

- Order Pickers: These forklifts are designed to pick items directly from the shelves, making them highly useful in order picking operations.

- Counterbalance Forklifts: These are the most common forklifts in warehouses, as they are flexible and can be used for a wide range of tasks, from moving heavy loads to lifting items onto high shelves.

How Forklifts Improve Logistics and Productivity:

- Increased Efficiency: Forklifts allow warehouses to maximize space and speed up the process of storing and retrieving goods. They can montacargas or lift heavy loads and transport them across long distances with ease, significantly improving logistics and the turnaround time for shipments.

- Streamlined Operations: Forklifts reduce the manual labor required in warehouses, allowing businesses to handle more goods with fewer resources. Automated systems and automated guided vehicles (AGVs) are increasingly being used in combination with forklifts to further enhance efficiency and productivity.

- Safety: Forklifts are designed to reduce the risk of injury by offering safer handling and transportation of heavy loads compared to manual lifting. With the right training, operators can use forklifts to ensure a safer work environment.

Effective performance management systems in warehouses rely heavily on equipment like forklifts. By monitoring forklift performance, managers can ensure optimal material handling and address any inefficiencies that might arise.

Forklifts in Construction

Forklifts in construction sites help move heavy materials, equipment, and tools, enabling projects to stay on track and within budget. Different types of forklifts are utilized based on the nature of the construction work and the site conditions.

Types of Forklifts Used in Construction Sites:

- Telehandlers: Telehandlers, also known as telescopic forklifts, are commonly used on construction sites because of their long-reaching arms. They can lift heavy materials to high elevations, such as loading construction materials onto scaffolding or hoisting equipment up to high floors.

- Rough Terrain Forklifts: These forklifts are designed with large, durable tires to traverse uneven terrain. They are essential for construction sites that involve moving materials over rough ground, such as building foundations or outdoor projects.

- Straight Mast Forklifts: These forklifts have a more compact design and are used for lifting and moving heavy loads on construction sites. Their large wheels and powerful engines make them effective for outdoor and rugged conditions.

Advantages of Specialized Forklifts like Telehandlers and Rough Terrain Models:

- Versatility: Forklifts like telehandlers are versatile and can be equipped with a variety of attachments, including forks, buckets, and lifts, allowing them to perform a wide range of tasks on construction sites.

- Adaptability to Challenging Conditions: Rough terrain forklifts can handle uneven and challenging environments, making them ideal for construction sites with dirt, gravel, or debris. They can navigate over obstacles and make lifting operations more efficient in these rugged conditions.

- Increased Productivity: Specialized forklifts help construction workers move materials more efficiently, reducing downtime and ensuring projects stay on schedule.

Forklifts in Manufacturing and Shipping

In manufacturing and shipping operations, forklifts are an integral part of material handling, ensuring that raw materials and finished products are transported efficiently across production lines, warehouses, and shipping docks.

Key Forklifts in Factories and Port Operations:

- Electric Counterbalance Forklifts: These forklifts are ideal for indoor use in factories and shipping operations. They offer precise maneuverability and are capable of handling a variety of tasks, such as moving raw materials from one point to another or lifting finished products onto storage racks.

- Container Handlers: These forklifts are designed for heavy-duty operations at ports and shipping yards. They are capable of lifting and stacking shipping containers efficiently, making them essential for port operations.

- Reach Stackers: Similar to container handlers, reach stackers are used in shipping ports to stack containers on top of one another, allowing for optimal storage space in the yard.

- High-Capacity Forklifts: In manufacturing, high-capacity forklifts are required to move large, heavy components across the production floor, such as engine parts, steel beams, or assembly-line materials.

How Forklifts Benefit Manufacturing and Shipping:

- Increased Efficiency in Production: Forklifts ensure that raw materials are delivered quickly to the production line and that finished products are transported efficiently to storage or shipment areas. This speeds up production timelines and ensures that inventory is maintained without delays.

- Improved Safety: Forklifts help reduce the risk of injury and damage to materials by taking over the heavy lifting tasks. Forklift operators, when properly trained, can move materials safely across manufacturing floors or shipping docks without exposing themselves to unnecessary risks.

- Better Space Utilization: Forklifts, especially reach trucks and stackers, can help maximize warehouse and storage space by efficiently storing materials and products in vertical configurations, which enhances warehouse capacity and stock organization.

Forklifts in modern industries, such as warehouses and manufacturing, are increasingly integrated with digital systems. API integration is crucial for tracking and optimizing the performance of forklifts through real-time data, enhancing operational efficiency.

Forklift Maintenance and Care

Forklifts, like all industrial equipment, require regular maintenance and care to ensure their longevity, reliability, and safe operation. By taking the necessary steps to maintain and care for a forklift, you can maximize its performance, reduce downtime, and avoid costly repairs. Below, we discuss some essential tips for forklift maintenance, along with common issues and troubleshooting tips that every forklift operator should know.

Tips for Ensuring Forklift Longevity

Forklifts are heavy-duty machines, and like any other vehicle, they require routine care to function optimally. Proper care not only extends the life of your forklift but also keeps it safe and compliant with industry regulations.

- Regular Cleaning and Inspections:

- Clean your forklift regularly to prevent dirt, debris, and grease from building up. This ensures that the moving parts function properly and that there is no obstruction to any components.

- Perform daily inspections, including checking for visible damage, tire wear, and hydraulic fluid levels. This helps in identifying issues before they become serious problems.

- Clean your forklift regularly to prevent dirt, debris, and grease from building up. This ensures that the moving parts function properly and that there is no obstruction to any components.

- Battery Care:

- If your forklift is electric, taking care of the battery is critical. Regularly charge the battery, avoid overcharging, and ensure it is maintained according to the manufacturer’s guidelines.

- Check the battery terminals for corrosion and clean them if necessary. Corrosion can reduce battery life and performance.

- Ensure that the battery water level is adequate, as low water levels can cause the battery to overheat and shorten its life.

- If your forklift is electric, taking care of the battery is critical. Regularly charge the battery, avoid overcharging, and ensure it is maintained according to the manufacturer’s guidelines.

- Oil and Hydraulic Fluid Checks:

- Regularly check and change the oil and hydraulic fluid in your forklift. Over time, these fluids can break down or become contaminated, leading to poor performance.

- Use the right type of oil or fluid specified by the manufacturer to ensure smooth operation of the engine and hydraulic systems.

- Regularly check and change the oil and hydraulic fluid in your forklift. Over time, these fluids can break down or become contaminated, leading to poor performance.

- Tire Checks and Replacement:

- Inspect the forklift tires regularly for any damage, wear, or uneven wear patterns. Tires are an essential part of forklift safety and performance, and underinflated or damaged tires can lead to accidents and costly repairs.

- Replace tires when needed. Solid tires are often preferred for industrial use because they last longer and require less maintenance compared to pneumatic tires.

- Inspect the forklift tires regularly for any damage, wear, or uneven wear patterns. Tires are an essential part of forklift safety and performance, and underinflated or damaged tires can lead to accidents and costly repairs.

Regular Maintenance Tasks

Here are some of the key tasks you should perform regularly to keep your forklift in top condition:

- Engine and Hydraulic System Checks:

- Perform regular checks on the forklift’s engine and hydraulic system to ensure there are no leaks or performance issues.

- Regularly change the engine oil and replace filters when required to keep the engine running smoothly.

- Perform regular checks on the forklift’s engine and hydraulic system to ensure there are no leaks or performance issues.

- Lubrication of Moving Parts:

- Lubricate the forklift’s moving parts, including chains, gears, and hydraulic arms, to prevent friction and wear. This helps in keeping the forklift efficient and reducing the risk of breakdowns.

- Lubricate the forklift’s moving parts, including chains, gears, and hydraulic arms, to prevent friction and wear. This helps in keeping the forklift efficient and reducing the risk of breakdowns.

- Brake System Maintenance:

- Brake maintenance is crucial for forklift safety. Regularly inspect the brake system, ensuring that pads are not worn down and that the system operates effectively. Malfunctioning brakes can be dangerous and cause accidents.

- Brake maintenance is crucial for forklift safety. Regularly inspect the brake system, ensuring that pads are not worn down and that the system operates effectively. Malfunctioning brakes can be dangerous and cause accidents.

- Fork and Mast Inspection:

- Inspect the forks and mast regularly for any cracks or damage. Forks should be properly aligned and should not have any bending or deformation. A damaged forktruck can cause instability when lifting loads.

Common Forklift Issues and Troubleshooting Tips

Even with regular maintenance, forklifts can face issues from time to time. Here are some common problems and troubleshooting tips:

- Forklift Won’t Start:

- Battery-related issues are often the cause of a forklift not starting, especially for electric models. Check the battery charge, terminals, and connections. For gas-powered forklifts, ensure that the fuel tank is full, and check for issues with the ignition system.

- Battery-related issues are often the cause of a forklift not starting, especially for electric models. Check the battery charge, terminals, and connections. For gas-powered forklifts, ensure that the fuel tank is full, and check for issues with the ignition system.

- Hydraulic System Malfunctions:

- If the forklift’s hydraulic lift is not functioning correctly, it may be due to low hydraulic fluid levels or leaks in the system. Check the hydraulic fluid and hoses for leaks and ensure the pump is working properly.

- Air in the hydraulic system can cause it to malfunction. Bleed the system to remove any trapped air.

- If the forklift’s hydraulic lift is not functioning correctly, it may be due to low hydraulic fluid levels or leaks in the system. Check the hydraulic fluid and hoses for leaks and ensure the pump is working properly.

- Tire Issues:

- For pneumatic tire forklifts, flat tires or tires losing air pressure can cause problems. Inspect the tires for punctures, and if necessary, inflate them to the correct pressure.

- For solid tires, check for cracks or damage and replace them when necessary.

- For pneumatic tire forklifts, flat tires or tires losing air pressure can cause problems. Inspect the tires for punctures, and if necessary, inflate them to the correct pressure.

- Overheating:

- If the forklift is overheating, it could be due to low coolant levels, a faulty radiator, or a clogged air filter. Check and replace filters, ensure proper coolant levels, and clean the radiator regularly to avoid overheating issues.

- If the forklift is overheating, it could be due to low coolant levels, a faulty radiator, or a clogged air filter. Check and replace filters, ensure proper coolant levels, and clean the radiator regularly to avoid overheating issues.

- Forklift Leaks:

- Leaks in hydraulic systems or engines can lead to performance issues and are often caused by damaged seals, hoses, or fittings. Inspect the forklift for any leaks, and replace damaged components immediately to prevent further issues.

- Leaks in hydraulic systems or engines can lead to performance issues and are often caused by damaged seals, hoses, or fittings. Inspect the forklift for any leaks, and replace damaged components immediately to prevent further issues.

- Poor Fork Performance:

- If the forks are not lifting properly or seem to be sluggish, it may be due to worn-out parts in the mast or hydraulic system. Inspect these parts and replace them as necessary to restore proper performance.

To ensure the proper functioning of forklifts, data verification systems can be employed to track maintenance schedules, usage statistics, and battery health, helping operators prevent unexpected breakdowns.

Conclusion

In summary, what is a forklift? It is an essential piece of industrial equipment used for lifting and transporting materials in various sectors, including warehouses, construction sites, and manufacturing plants. By understanding the different types of forklifts, their components, and how they work, businesses can make informed decisions about the equipment that best suits their needs, ensuring safety and efficiency.

Whether you’re looking to rent, buy, or maintain a forklift, proper knowledge and training are key to maximizing its lifespan and performance. With the right forklift, along with regular maintenance and safety practices, companies can enhance their productivity while minimizing risks.

FAQs

Is a forklift a lift truck?

Yes, a forklift is a type of lift truck specifically designed to handle materials by lifting them with forks.

What are the three types of forklifts?

The three main types are counterbalance forklifts, reach trucks, and pallet jacks.

What is a forklift classified as?

A forklift is classified as a powered industrial truck used for material handling.

Which are the key components of a forklift?

The key components include the mast, forks, carriage, wheels, power source, and hydraulic system.

Which controls are required for operating a forklift successfully?

Essential controls include steering, accelerator, brakes, hydraulic lift controls, and tilt functions.

What is the main function of a forklift?

The main function of a forklift is to lift, move, and stack heavy loads efficiently in warehouses, construction sites, and factories.

Which power sources are available for forklifts to choose from?

Forklifts can be powered by electricity, internal combustion engines (gasoline, diesel, or propane), or battery-powered systems.