Understanding Magnetic Metals | Are Lead, Iron, Steel, Copper, Aluminum, and More Magnetic?

Magnetic metals are materials that exhibit magnetic properties due to their atomic structure and electronic behavior. These metals are essential in various applications across industries, from electronics to construction, energy, and even medical devices. Understanding magnetic metals and their properties can provide insight into their uses, as well as help to identify which materials are magnetic and why.

This article will explore the world of magnetic metals, focusing on the types of metals that are magnetic, their characteristics, and how they interact with magnetic fields. It will also cover why certain metals, such as aluminum and copper, are not magnetic, despite being widely used in various technological applications.

What Are Magnetic Metals?

Magnetic metals are materials that can be influenced by a magnetic field. The key property that makes a metal magnetic is its atomic structure, which allows for the alignment of electrons in a way that generates a magnetic field. Metals that can align their magnetic domains (regions where atoms are magnetically aligned) are considered magnetic.

There are various types of magnetic metals, each with distinct properties, and their magnetic characteristics are classified into different categories. Understanding these categories is essential for knowing which metals can be used in specific applications, such as making magnets or generating electricity.

Types of Magnetic Metals

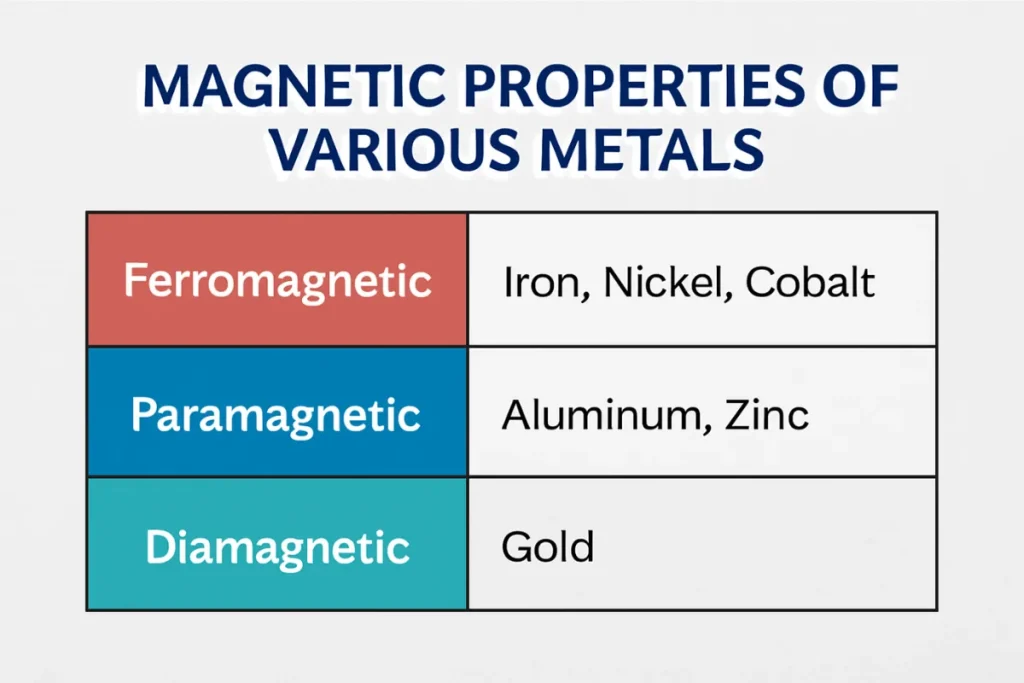

Magnetic metals can be divided into three main categories: ferromagnetic, paramagnetic, and diamagnetic. Each category represents a different level of magnetic interaction.

Ferromagnetic Metals

Ferromagnetic metals are the most strongly magnetic metals. They include elements like iron, nickel, cobalt, and some of their alloys. Ferromagnetic metals have magnetic domains that can be aligned, allowing them to become permanent magnets. These metals are attracted to magnets and can be magnetized themselves.

- Iron: Iron is the most common ferromagnetic material. It is used in the production of magnets, and its magnetic properties make it essential for various electrical devices, such as transformers and electric motors.

- Nickel: Nickel is often used in magnets due to its high magnetic permeability. It is also used in alloys, such as in the creation of Alnico magnets, which are made by combining iron, nickel, and aluminum.

- Cobalt: Cobalt is another ferromagnetic metal that is commonly used in industrial magnets. It has a high Curie temperature, which means it retains its magnetic properties at higher temperatures.

Paramagnetic Metals

Paramagnetic metals are only weakly attracted to magnetic fields. Unlike ferromagnetic metals, paramagnetic metals do not retain their magnetic properties once the external magnetic field is removed. Examples of paramagnetic metals include aluminum, platinum, and titanium.

- Aluminum: Aluminum is a widely used metal in industries such as aerospace and packaging. While it is not magnetic in its natural state, it can be slightly attracted to strong magnetic fields due to its paramagnetic properties.

- Platinum: Platinum is another paramagnetic metal. Though it has a weak interaction with magnetic fields, it is used in certain electronic applications due to its high resistance to corrosion and stability.

Diamagnetic Metals

Diamagnetic metals are materials that are weakly repelled by magnetic fields. Unlike ferromagnetic and paramagnetic metals, diamagnetic metals do not show any attraction to magnetic fields. They include copper, silver, gold, and bismuth.

- Copper: Copper is a non-magnetic metal, meaning that it does not attract magnets. While it is an excellent conductor of electricity, its magnetic properties are negligible. However, copper is still important in the production of electrical motors and generators due to its conductivity.

- Silver: Silver, like copper, is diamagnetic. It is also widely used in electrical and electronic components, but does not exhibit significant magnetic properties.

Key Magnetic Metals and Their Applications

Magnetic metals are essential in numerous technological and industrial applications. The properties of these metals make them ideal for use in electric motors, generators, transformers, and other devices that rely on magnetic fields. Here is an overview of some of the most widely used magnetic metals:

Iron: The Backbone of Magnetism

Iron is one of the most commonly used magnetic metals. It is the primary material used in the creation of permanent magnets, such as those found in motors, speakers, and hard drives. Iron’s magnetic properties make it ideal for use in generating magnetic fields in electrical devices. The soft iron variety is particularly used in applications where temporary magnetism is needed.

Uses:

- Motors and Generators: Iron is widely used in electrical motors and generators due to its excellent magnetic properties.

- Transformers: Iron is also used in transformers, which are essential components in power distribution systems.

Nickel: Versatile and Magnetic

Nickel is widely used in making alloys that have strong magnetic properties. It is a key element in the creation of Alnico magnets (a blend of aluminum, nickel, and cobalt), which are used in a variety of applications, from small electronics to large industrial machinery.

Uses:

- Electronics: Nickel’s magnetic properties make it valuable in the electronics industry, where it is used in the production of magnetic storage devices and batteries.

- Magnetic Alloys: Nickel is often mixed with other metals like iron and cobalt to create high-strength magnets for use in motors and speakers.

Cobalt: Industrial Magnets and High-Temperature Applications

Cobalt is a key component in many high-performance magnets. It is used in high-temperature magnets, which are essential for devices operating under extreme conditions. Cobalt’s ability to retain its magnetic properties at elevated temperatures makes it crucial for aerospace and other high-tech industries.

Uses:

- Permanent Magnets: Cobalt is used in the production of permanent magnets, especially in high-performance applications like electric motors and aircraft systems.

- Batteries: Cobalt is also used in the manufacturing of rechargeable batteries, such as those used in electric vehicles.

Magnetic Properties of Various Metals

The ability of a metal to respond to magnetic fields depends on the electron configuration and atomic structure. In magnetic metals, atoms align in a way that allows them to interact with an external magnetic field, either by attracting or repelling it.

Much like the double bottom pattern in stock market analysis, which signals a reversal or stable point, the alignment of magnetic domains in ferromagnetic materials can signal the formation of a strong, stable magnetic field.

Magnetic Behavior in Everyday Materials

Many materials that are not typically magnetic may show some magnetic effects when exposed to a sufficiently strong magnetic field. This phenomenon is particularly seen in paramagnetic and diamagnetic metals, which interact with magnetic fields in subtle ways.

Just as NWT (New With Tags) indicates the authenticity and condition of an item, the magnetic properties of a material can indicate its ability to interact with external magnetic fields, marking its behavior as either magnetic or non-magnetic.

Magnetic Properties in Everyday Materials

Magnetic materials are not always immediately apparent in everyday life. While some metals exhibit strong magnetic properties, others might show only a faint response when exposed to a magnetic field. It’s crucial to understand the subtle differences between various materials to know how they will behave when in the presence of magnets.

Do Magnets Stick to Brass, Bronze, or Lead?

Brass, bronze, and lead are not magnetic metals. These are examples of non-ferromagnetic materials, which means they don’t exhibit the strong magnetic properties that metals like iron, cobalt, and nickel do.

- Brass: Brass is a copper-zinc alloy and does not have the atomic structure that allows it to be magnetized. Although it is often used in electrical connectors and mechanical parts, it remains unaffected by a magnetic field.

- Bronze: Like brass, bronze is an alloy (primarily copper and tin) that does not show any ferromagnetic properties. While it has various applications, particularly in coins, musical instruments, and sculptures, it’s not suitable for use in applications that require magnetic properties.

- Lead: Lead, a heavy and soft metal, is also non-magnetic. It’s used primarily in construction, batteries, and radiation shielding, but it’s not affected by magnetic fields.

Does Steel Stick to Magnets?

Steel, which is primarily composed of iron, is generally magnetic. However, the behavior of steel in a magnetic field depends on the type of steel:

- Carbon Steel: Carbon steel, due to its iron content, is ferromagnetic and can be magnetized. It is often used in the manufacturing of magnets and magnetic components.

- Stainless Steel: Stainless steel is an alloy of iron, carbon, and other metals like chromium and nickel. It is typically non-magnetic or only weakly magnetic due to its composition. However, some types of stainless steel, such as martensitic stainless steel, can exhibit magnetic properties because of their high iron content.

Thus, whether steel is attracted to a magnet depends on its alloying elements and the specific grade of steel.

Just as a fair value gap reflects an imbalance or difference in market conditions, certain materials like copper or aluminum exhibit a gap in their magnetic properties, being less responsive or even repelled by magnets compared to ferromagnetic materials.

Do Magnets Stick to Copper?

Copper, a widely used non-ferrous metal, is diamagnetic, meaning it is weakly repelled by magnetic fields. Unlike ferromagnetic materials, copper doesn’t form magnetic domains that can align in response to a magnetic field, so it doesn’t become magnetized. However, copper does have an interesting relationship with magnetic fields.

- Copper in Electromagnetic Applications: Copper is frequently used in the windings of electric motors and transformers due to its excellent electrical conductivity. Even though copper is not magnetic, its ability to conduct electricity allows it to interact with changing magnetic fields, creating electric currents in a process called electromagnetic induction.

Does Copper Stick to a Magnet?

Copper itself does not stick to magnets. Unlike ferromagnetic materials like iron or nickel, copper does not exhibit any magnetic properties under normal conditions. While copper can be magnetized in certain circumstances, such as in an electromagnet, its natural state is non-magnetic.

How to Magnetize Metals

Magnetizing a metal means aligning the magnetic domains in a material so that it becomes a magnet. The ability to magnetize a metal is directly related to its atomic structure and the types of magnetic domains it possesses.

How to Magnetize Iron, Steel, and Other Metals

Ferromagnetic metals, such as iron and steel, are easier to magnetize compared to non-ferromagnetic metals like copper and aluminum. Here are the steps to magnetize metals:

- Apply a Strong Magnetic Field: The most common method to magnetize ferromagnetic metals is by placing the metal in a strong magnetic field. The metal’s magnetic domains will align with the magnetic field, thus magnetizing the material.

- Rub with a Magnet: A more hands-on approach involves rubbing a permanent magnet along the metal in a single direction. This method can help align the magnetic domains within the metal, magnetizing it.

- Electric Current: Passing an electric current through a coil of wire surrounding the metal (creating an electromagnet) is another way to magnetize the material. The magnetic field generated by the current aligns the magnetic domains in the metal, turning it into a magnet.

The magnetization process works best with ferromagnetic metals like iron, steel, and nickel, as these metals possess the right atomic structure to allow their domains to align.

What Makes a Metal Magnetic?

Magnetic properties arise from the interaction of electrons within atoms. The magnetic properties of a material depend on its atomic structure and the behavior of electrons in response to external magnetic fields. Here’s a breakdown:

- Ferromagnetism: In ferromagnetic materials, atoms have unpaired electrons, and these electrons align in the same direction, forming magnetic domains. When the magnetic domains are aligned, the material exhibits a strong magnetic field.

- Electron Configuration: In non-magnetic materials, such as copper or gold, the electrons pair up, canceling out any magnetic effects. In contrast, ferromagnetic metals have unpaired electrons that contribute to the material’s magnetism.

Can All Metals Be Magnetized?

Not all metals can be magnetized. Metals like copper, gold, and aluminum are not magnetic because their atomic structures prevent the alignment of magnetic domains. However, they may still interact with magnetic fields in some ways:

- Copper: Copper is diamagnetic and will be weakly repelled by magnets.

- Aluminum: While aluminum is paramagnetic (weakly attracted to a magnetic field), it doesn’t become magnetized in the way iron does.

However, certain non-ferromagnetic metals can still play a role in electromagnetic applications, where their conductive properties interact with magnetic fields, even though they do not exhibit inherent magnetism.

What Are Permanent and Temporary Magnets?

Permanent magnets are materials that retain their magnetic properties for an extended period. These magnets don’t need an external power source to maintain their magnetism. The most common permanent magnets are made from ferromagnetic metals such as iron, nickel, and cobalt.

On the other hand, temporary magnets can become magnetized when exposed to a magnetic field but lose their magnetism once the external field is removed. For example, soft iron is often used in electromagnets due to its ability to become magnetized in a magnetic field and return to its non-magnetic state when the field is removed.

Examples of Permanent Magnets:

- Neodymium Magnets: These are rare-earth magnets made from alloys of neodymium, iron, and boron, and they are incredibly strong.

- Alnico Magnets: Made from aluminum, nickel, cobalt, and iron, these magnets are used in motors and sensors.

Examples of Temporary Magnets:

- Soft Iron: This metal is often used in electromagnetic devices, such as electric bells, where it becomes temporarily magnetized in the presence of a magnetic field.

Magnetic Metals in Technology and Industry

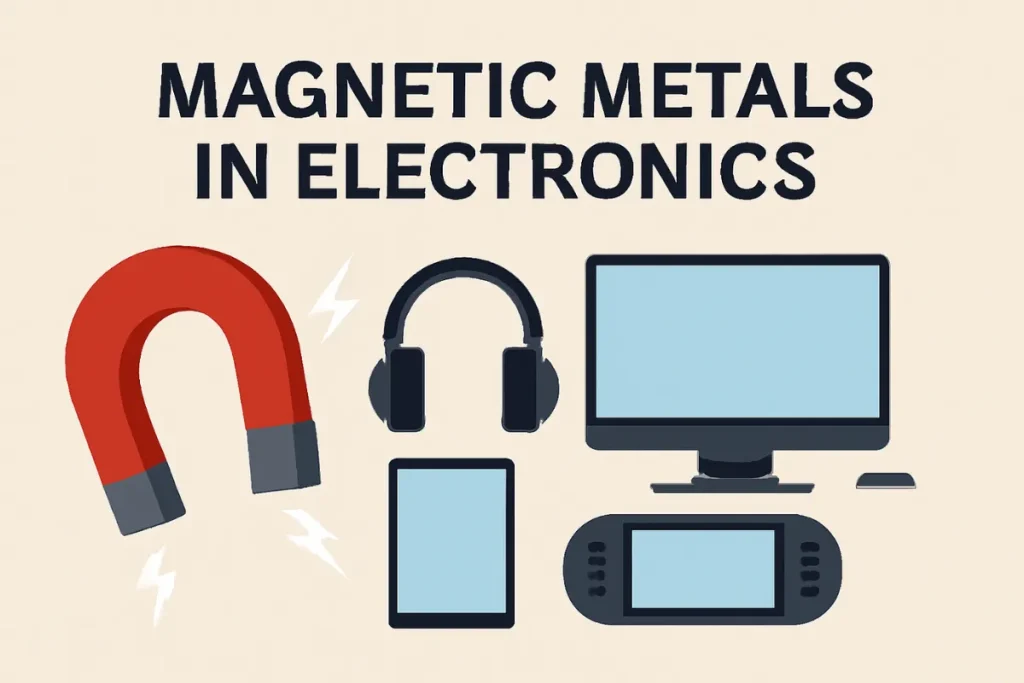

Magnetic metals are at the core of many technological advancements. Their ability to generate and interact with magnetic fields is harnessed in applications ranging from electronics to energy generation.

Similar to how DDR6 memory improves performance by offering faster data speeds, the magnetic properties of metals like iron and cobalt enhance the efficiency of electronic devices by allowing for optimal interactions with magnetic fields.

Magnetic Metals in Electronics

In the electronics industry, magnetic metals are integral to devices like hard drives, electric motors, speakers, and transformers. For example, permanent magnets are used in loudspeakers, where their magnetic field interacts with a coil of wire to produce sound.

- Electric Motors: These devices use magnetic fields to generate rotational motion, and the materials used in the magnets, like iron and cobalt, directly influence the efficiency of the motor.

- Hard Drives: Magnetic metals, especially iron and nickel, are used in the production of magnetic storage devices like hard drives, where data is written and read through the magnetic properties of the disks.

Much like how a USB device not recognized error can interrupt the smooth functioning of a system, issues with the alignment of magnetic domains can impact the effectiveness of electronic devices like motors or hard drives.

Magnetic Metals in Power Generation

Magnetic metals are essential for generating electricity. Wind turbines, electric generators, and transformers all rely on magnetic fields to function.

- Generators: In a generator, a magnet is rotated within a coil of wire to produce an electric current.

- Transformers: Magnetic metals, such as iron, are used to create magnetic cores in transformers, which transfer electrical energy between circuits.

Just as a headphone dent can affect the performance of audio equipment, slight imperfections or inconsistencies in the magnetic properties of materials can influence the performance of magnetic devices in industries like electronics and energy generation.

Why Are Some Materials Not Magnetic?

Not all materials exhibit magnetic properties. The reason why certain metals, such as gold, aluminum, and copper, are not magnetic boils down to their atomic and electronic structures.

Why Some Metals Aren’t Magnetic

Magnetism in metals is largely determined by the arrangement of electrons in the atoms. The key difference between magnetic and non-magnetic materials is whether the magnetic domains within the material can align with each other. Magnetic materials, like iron, nickel, and cobalt, have atoms with unpaired electrons that align in the same direction, forming magnetic domains. In contrast, non-magnetic materials do not have aligned domains, preventing them from becoming magnetized.

For example, copper and aluminum have electron configurations that prevent them from forming magnetic domains. As a result, these metals remain non-magnetic even though they are widely used in various applications, such as electrical wiring, due to their excellent conductivity.

- Copper: Copper is a diamagnetic material, meaning it is weakly repelled by magnetic fields. However, copper cannot become magnetized and does not produce a magnetic field.

- Aluminum: Aluminum is paramagnetic, which means it is weakly attracted to a magnetic field. However, like copper, it doesn’t become magnetized or retain any magnetic properties.

What Are Magnets Made Of?

Most magnets are made from ferromagnetic metals like iron, nickel, cobalt, and their alloys. These metals have a unique electron structure that allows them to generate magnetic fields when their domains align. Magnets can be permanent or temporary, depending on the metal and the way it is processed.

- Permanent Magnets: Permanent magnets are made from ferromagnetic metals like iron, nickel, and cobalt. These metals retain their magnetic properties without needing an external power source, and they are used in a variety of devices such as speakers, motors, and hard drives.

- Electromagnets: Electromagnets are created by wrapping a coil of wire around a metal core (often made of iron) and passing an electric current through the coil. The flow of electricity generates a magnetic field, and the iron core helps to amplify this field. Electromagnets can be turned on or off by controlling the current.

Just as chat bubbles organize communication for clarity and effective interaction, the elements used to create magnets (such as iron, nickel, and cobalt) align in a way that produces a coherent magnetic field.

What Materials Are Magnetic?

Some metals naturally exhibit magnetic properties. These materials are called magnetic materials and can be further classified based on the strength of their magnetism.

Ferromagnetic Materials

These materials can be magnetized and retain their magnetism. Examples include:

- Iron

- Nickel

- Cobalt

Paramagnetic Materials

These materials are weakly attracted to magnetic fields but do not retain their magnetism once the field is removed. Examples include:

- Aluminum

- Platinum

- Magnesium

Diamagnetic Materials

These materials are weakly repelled by magnetic fields. Examples include:

- Copper

- Gold

- Silver

Magnetic Alloys

Many magnets are alloys—mixtures of two or more metals—designed to enhance magnetic properties. These magnetic alloys combine the properties of different metals to optimize performance for specific applications.

Alnico Magnets

One of the most well-known types of magnetic alloys is Alnico, a blend of aluminum, nickel, cobalt, and iron. Alnico magnets are used in applications like electric motors, guitar pickups, and sensors.

Properties:

- Strong magnetic field.

- High temperature resistance.

- Commonly used in industrial applications.

Samarium Cobalt (SmCo)

Samarium Cobalt magnets are rare-earth magnets that are highly resistant to demagnetization. These magnets are made from a combination of samarium and cobalt and are used in applications where high performance is required.

Properties:

- High magnetic strength.

- High corrosion resistance.

- Ideal for high-temperature applications.

Neodymium (NdFeB) Magnets

Neodymium magnets are another type of rare-earth magnet, made from an alloy of neodymium, iron, and boron. These magnets are among the strongest permanent magnets available, and they are used in a wide range of applications, from hard drives to wind turbines.

Properties:

- Extremely strong magnetic field.

- Used in high-tech applications like robotics and electric vehicles.

Does Aluminum Stick to a Magnet?

Aluminum is a non-ferromagnetic material, meaning it is not attracted to magnets. However, aluminum is paramagnetic, which means it will be weakly attracted to a magnetic field, although it will not stick to the magnet once the field is removed. This is in stark contrast to metals like iron or steel, which are strongly attracted to magnets due to their ferromagnetic properties.

Despite not being magnetic in the traditional sense, aluminum plays an essential role in various industries due to its strength, lightweight nature, and corrosion resistance. It is commonly used in aircraft manufacturing, electrical wiring, and packaging materials.

How Do Magnetic Fields Interact with Metals?

Magnetic fields interact with metals in various ways, depending on the magnetic properties of the material. When a ferromagnetic material is exposed to a magnetic field, its magnetic domains align, and the material itself becomes magnetized. The material will exhibit attraction or repulsion to other magnets depending on the alignment of its magnetic poles.

Magnetic Field Lines

Magnetic field lines are the invisible paths that magnetic forces follow. These lines always extend from the north pole to the south pole of a magnet. The magnetic field lines become denser when interacting with ferromagnetic metals, indicating a stronger magnetic field. The stronger the material’s magnetic properties, the more significant its ability to concentrate magnetic field lines.

Interaction with Non-Magnetic Materials

Non-ferromagnetic materials like copper, aluminum, and gold do not interact significantly with magnetic fields. However, in certain circumstances, like in electromagnetic induction, these materials can be influenced by changing magnetic fields, causing them to produce an electric current.

How to Make Metal Magnetic

Making a metal magnetic involves aligning its magnetic domains. This can be done in a variety of ways, including:

- Exposing the Metal to a Magnetic Field: When ferromagnetic metals are placed in a strong magnetic field, the atoms within the material align their magnetic domains, magnetizing the metal.

- Electromagnetism: Using an electric current to produce a magnetic field is another method for magnetizing metals. When a metal is placed inside a coil through which current flows, the metal will be magnetized.

- Hammering or Rubbing: Rubbing or hammering a magnet across a metal surface can also help align the domains in ferromagnetic materials, magnetizing them.

Is Titanium Magnetic?

Titanium is non-magnetic in its natural state. Despite being a highly useful material in many industries (e.g., aerospace, medical implants, and jewelry), titanium does not exhibit magnetic properties. However, titanium can interact with magnetic fields under certain conditions, but it does not become a permanent magnet.

- Why Isn’t Titanium Magnetic?: Titanium’s atomic structure prevents it from forming the magnetic domains required for ferromagnetism. While it can conduct electricity, its electron configuration prevents it from becoming magnetized.

Magnetism in Lead and Bronze

Both lead and bronze are non-magnetic materials.

- Lead: Lead is diamagnetic, meaning it is weakly repelled by magnetic fields. Lead’s dense nature makes it ideal for shielding applications, such as in radiation protection, but it does not interact significantly with magnets.

- Bronze: Similar to brass, bronze is an alloy, typically of copper and tin, and does not exhibit magnetic properties. While bronze is valued for its durability and resistance to corrosion, it does not react with magnetic fields.

Conclusion

Magnetic metals are an essential part of many modern technologies, from electronics to power generation and transportation. The ability of certain metals to interact with magnetic fields, either by becoming magnetized or by influencing the field around them, is critical for the operation of devices like motors, speakers, hard drives, and transformers. While iron, nickel, and cobalt are the most common magnetic metals, other materials like copper and aluminum can play important roles in electromagnetic applications, even though they are not magnetic.

Understanding the properties of magnetic metals allows us to make informed decisions about material selection in various industries and innovations. From permanent magnets to electromagnets, the applications of magnetic metals are vast and diverse, powering much of the technology we rely on every day.

FAQs

What Are the 7 Magnetic Elements?

The seven magnetic elements are those that exhibit ferromagnetic properties, meaning they can be magnetized and interact strongly with a magnetic field. These elements include:

- Iron (Fe): The most well-known magnetic element.

- Nickel (Ni): Commonly used in alloys for magnet creation.

- Cobalt (Co): Used in high-performance magnets and alloys.

- Gadolinium (Gd): A rare-earth element that exhibits magnetic properties at low temperatures.

- Dysprosium (Dy): Often used in high-performance magnets.

- Terbium (Tb): A rare-earth element with magnetic properties, often used in advanced magnets.

- Samarium (Sm): A rare-earth element used in samarium-cobalt magnets.

These elements are all ferromagnetic and are used in various industrial, technological, and consumer applications due to their magnetic properties.

What Metals Stick to a Magnet?

Ferromagnetic metals will stick to a magnet. These metals include:

- Iron: The most magnetic metal, widely used in magnets.

- Nickel: Attracted to magnets and used in the production of various magnets.

- Cobalt: Used in industrial and high-performance magnets.

- Steel: Composed mostly of iron, steel will generally stick to a magnet unless it’s specifically alloyed to reduce its magnetic properties.

- Magnetic Alloys: Some alloys, like Alnico, which contain iron, nickel, and cobalt, are magnetic and will stick to magnets.

Metals like aluminum, copper, and gold do not stick to magnets because they are non-ferromagnetic.

What Are the Top 5 Magnetic Materials?

The top five magnetic materials are those that exhibit strong magnetic properties, making them highly suitable for use in creating magnets and other magnetic applications. These include:

- Iron: The most commonly used magnetic material, known for its strong magnetic field.

- Nickel: Used in various industrial magnets and magnetic alloys due to its ferromagnetic properties.

- Cobalt: Offers high magnetic strength, especially in high-temperature applications.

- Neodymium (NdFeB): A rare-earth alloy known for producing incredibly strong magnets.

- Samarium-Cobalt (SmCo): Another rare-earth alloy that is highly resistant to demagnetization and can operate at high temperatures.

These materials are essential in many technologies, including electric motors, data storage devices, and medical imaging systems, where strong magnetic properties are needed.