Unlock Fiber Optic Color Codes & Color Chart for Flawless Setup

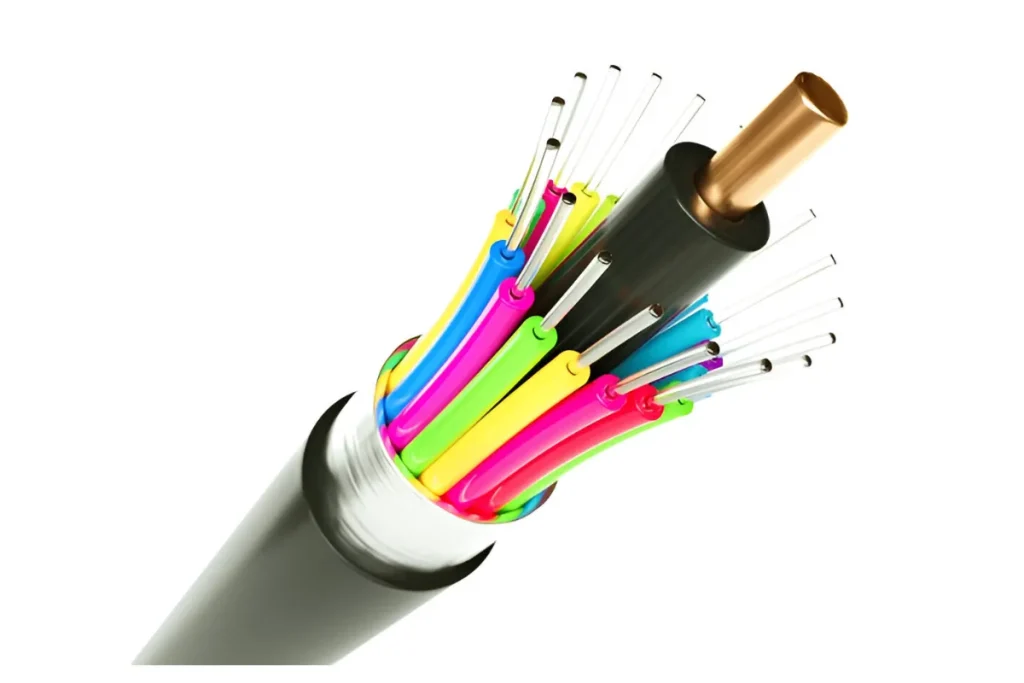

In the world of modern communication, fiber optic cables are the backbone of fast and reliable data transfer. Yet, for many, the complexity of fiber color codes can be overwhelming. Misunderstanding these codes can lead to errors in installation, splicing, and maintenance. These mistakes not only cause delays but can also disrupt entire networks. Whether you’re a technician, network designer, or just starting with fiber optics, understanding color codes is critical to avoid costly missteps.

Thankfully, there’s a solution. Fiber optic color codes follow standardized systems that simplify cable identification, organization, and troubleshooting. By mastering these codes, you can streamline installations, reduce errors, and ensure smooth operations. This guide breaks down fiber optic color coding, from cable jackets to connectors, and their role in building reliable networks.

Fiber Optic Cable and Connector Color Codes

Fiber optic color codes are a systematic way of identifying different cables and connectors. These codes are essential for ensuring that connections are made correctly and efficiently. The color codes are used to differentiate between various types of cables and connectors, making it easier for technicians to install, maintain, and troubleshoot fiber optic systems.

Color codes are also used in patch cords, which are crucial for connecting various devices in a network. Patch cords come in different colors to indicate their function and the type of fiber they carry.

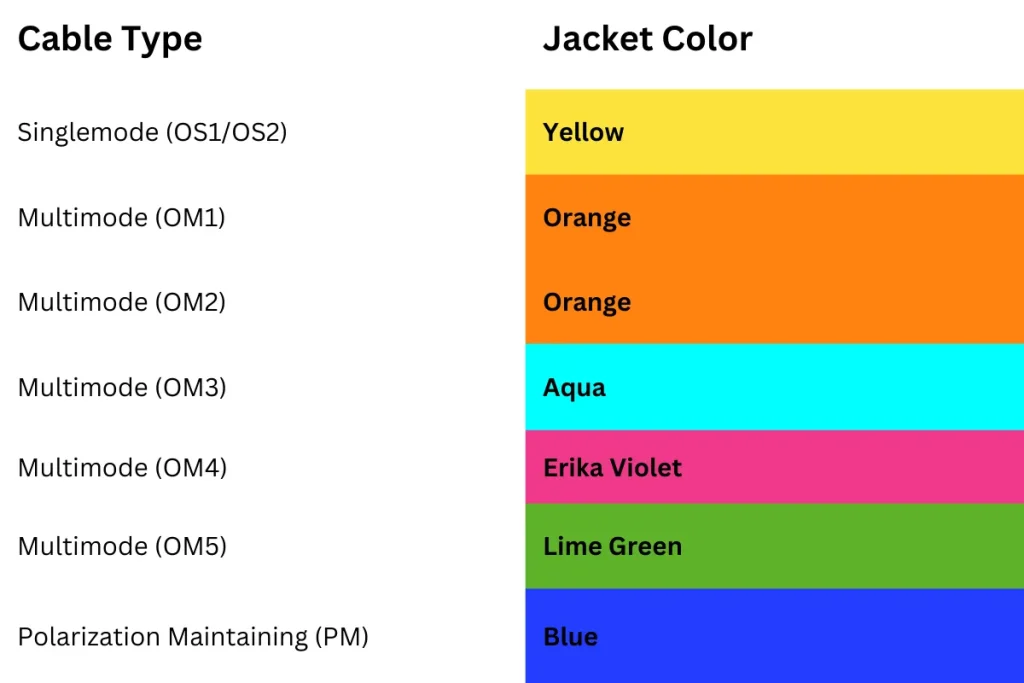

Types of Fiber Optic Cables and their colors

There are two main types of fiber optic cables: single-mode and multi-mode. Each type has its own unique characteristics and applications.

Single-mode Fiber Optic Cables

The core size of single mode cables is typically smaller (8-10 microns), designed for long-distance communication. The outer jacket of single mode cables is typically yellow, while connectors may be blue. This is especially important when distinguishing between different cable types during installation.

Single-mode fibers use color codes to identify different cables and connectors. The outer jackets are typically yellow, while connectors may be blue or black.

Multi-mode Fiber Optic Cables

Multi-mode cables have a larger core, usually around 50-62.5 microns in diameter. They are used for shorter distances and are ideal for local area networks (LANs) and data centers. Multi-mode fibers support multiple modes of light, which means that data can be transmitted in different paths within the fiber. This leads to higher modal dispersion but is suitable for short-range communication. Multi-mode fibers are commonly used for high-speed data transfer within buildings, campuses, and data centers.

The outer jackets are usually orange (OM1, OM2) or aqua (OM3, OM4). Connectors may be beige or aqua, depending on the type of multi-mode fiber.

|

Fiber Type |

Core Size (microns) |

Transmission Distance |

Applications |

|

Single-mode |

8-10 |

Long-distance |

Telecom networks, undersea cables, long-haul data transmission |

|

Multi-mode |

50-62.5 |

Short-distance |

LANs, data centers, high-speed data transfer within buildings and campuses |

Tight Buffered Cables vs. Loose Tube Cables

Tight buffered cables are typically used for indoor applications, and their color codes are standardized for easy identification. On the other hand, loose tube cables are used for outdoor installations, where the jacket colors are often black or yellow to indicate durability against environmental factors.

In comparison to fiber optic cables, the performance and applications of Cat5 and Cat6 cables differ significantly, catering to distinct networking needs.

Role of Color Coding in Cable Identification

Color coding is crucial for identifying and organizing fiber optic cables. It helps technicians quickly locate and identify specific cables, reducing the risk of errors during installation and maintenance. Without proper color coding, it would be challenging to distinguish between different types of fibers, leading to potential mix-ups and connectivity issues.

Importance of Color Coding

Color coding simplifies cable management and improves efficiency. Technicians can easily identify the type of cable and its purpose based on its color. This reduces the time spent on troubleshooting and ensures that the correct cables are used for each application.

Benefits of Color Coding

- Improved efficiency: Quick identification of cables.

- Reduced errors: Minimized risk of incorrect connections.

- Enhanced organization: Simplified cable management.

Color coding not only helps with cable identification but also plays a critical role in the organization of magnetic metals used in cable construction.

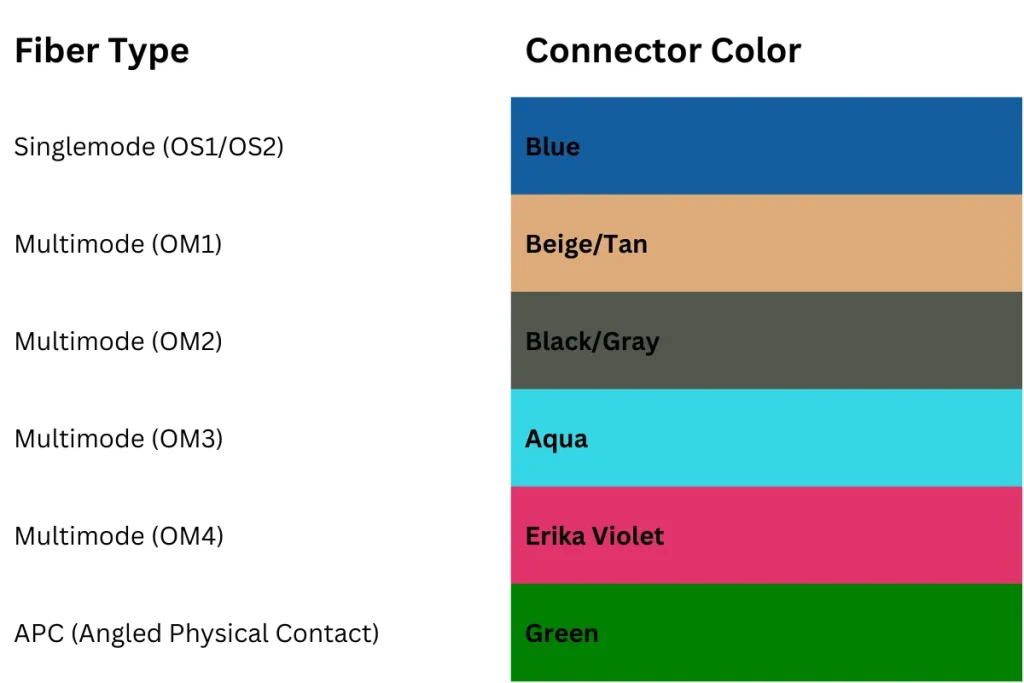

Connector Color Codes

Different types of connectors have specific color codes. This helps in port separation and identification in network setups. For example, blue connectors are used for single-mode fibers, while beige connectors are used for multi-mode fibers.

Different connector types such as SC, LC, and FC are color-coded based on the fiber type they are designed to connect to. The blue connector is typically used for single-mode fibers, while the beige connector is used for multi-mode fibers.

Connector Types Chart: By referencing a connector types chart, technicians can quickly identify which connectors correspond to the different types of cables they are working with, ensuring accurate connections every time.

12-Strand Code and 24-Strand Code in Fiber Optics

When working with high-count fiber optic cables (such as 12-strand code or 24-strand code), color coding helps technicians and network specialists to splice, test, and maintain cables with ease. The 12-strand code is widely used for simpler configurations, while 24-strand code cables are typically used for larger networks that require more complex connections.

Each strand within these cables follows a specific order of colors to ensure proper identification. For instance, the typical color sequence for a 24-strand code might include colors like blue, orange, green, and brown, arranged in a set order to make sure that every fiber is easily recognizable.

Port Separation and Identification

Proper color coding of connectors ensures clear identification and separation of ports, facilitating smooth network operations. This helps prevent mix-ups and ensures that the correct fibers are connected to the appropriate ports.

Using the 3Ps principle—Plan, Prepare, Perform—can streamline connector management, similar to how color coding standardizes connections.

Cable Jacket Colors Code

The outer jacket colors of fiber optic cables have specific significance. They help identify the type of fiber and its application. For example, orange jackets are used for multi-mode fibers, while yellow jackets are used for single-mode fibers. These colors provide a visual indication of the cable type, making it easier to identify and manage the cables.

Standards for Cable Jacket Colors

Cable jacket colors follow specific standards to ensure consistency in identification. These standards help technicians quickly determine the type of fiber and its intended use based on the jacket color.

Inner Fiber Color Code

Internal fibers within a cable also follow color codes, aiding in the organization and management of the fibers. These color codes help technicians identify individual fibers within a cable, making it easier to connect and splice them correctly.

Guidelines for Splicing and Continuity

Color codes play a crucial role in splicing fibers and maintaining continuity in the network. When splicing fibers, technicians must ensure that the color codes match on both ends of the splice to maintain proper connections and signal integrity.

Standards and Protocols

Explanation of TIA-598 Color Code Standards

The TIA-598 color code standards are widely adopted for fiber optic cable color coding. These standards provide a comprehensive guide for color coding in fiber optic cables, ensuring consistency and reliability across different installations.

The TIA/EIA-598 standards specify the color codes for both single-mode and multi-mode fibers, as well as the color codes for different types of connectors and cables. These standards are crucial for ensuring that fiber optic installations are consistent and meet industry requirements.

Other Standards: S12, DIN-0888, FIN2012, Standard Type E

Besides the TIA-598 standards, there are other standards used in different regions and industries. For instance, the S12 standard is commonly used in Europe, while DIN-0888 is used in Germany. The FIN2012 standard is used in Finland, and the Standard Type E is used in Japan. These standards provide guidelines for color coding and cable management in fiber optic installations, ensuring consistency and reliability.

Printable 864 Code Chart: This printable chart provides a quick reference for cables with up to 864 strands, helping technicians navigate large installations quickly.

Cable Code Chart PDF: Often provided by fiber optic manufacturers, these charts are downloadable for easy access during installation or maintenance.

Application of Standards in Different Fiber Types

Different fiber types, such as submarine cables and fiber ribbon cables, may require specific color coding standards. Submarine cables, used for undersea communication, often follow unique standards due to the harsh environmental conditions. Fiber ribbon cables, which consist of multiple fibers arranged in a ribbon-like structure, also have specific color coding standards to ensure proper identification and management.

Adhering to standards and protocols in fiber optics is as crucial as understanding the probability of default in financial models, ensuring reliability, and minimizing risks

Applications of Color Coding

Simplified Splicing

Color coding simplifies the splicing process by ensuring that fibers are correctly identified and matched. This reduces the risk of errors and ensures that connections are accurate and reliable.

Ease of Maintenance

Proper color coding aids in maintenance and troubleshooting. Technicians can quickly identify and locate specific fibers based on the color codes, making it easier to diagnose and resolve issues. This reduces downtime and ensures that the network remains operational.

Color coding not only simplifies network management but also enhances techniques like daisy chaining, making complex installations more manageable

Port Separation

Color coding helps in separating ports and ensuring that the correct fibers are connected to the appropriate ports. This is crucial for maintaining the integrity of the network and preventing connectivity issues.

As networks grow and scale, especially in the case of hyperscalers that support massive data centers, proper fiber optic color coding becomes crucial. These high-capacity systems require precise identification and organization to ensure smooth operations across vast, complex infrastructures.

Fewer Errors

Clear color coding reduces the chances of human errors during handling and connecting fibers. By following standardized color codes, technicians can ensure that the correct fibers are connected, minimizing the risk of connectivity issues.

Practical Guidance for Easy Memorization and Application

Here are some practical tips for memorizing and applying fiber optic color codes:

Mnemonics

Using mnemonics can help technicians quickly recall the color order of fibers. For example, the phrase “Big Oranges Grow Best So Why Run Back Yard Vegetables Round Again.” can be used to remember the standard color order.

Visual Guides

Visual guides, such as charts and diagrams, can provide a quick reference for color codes. These guides can be posted in work areas or included in training materials to help technicians learn and apply the codes.

Regular Practice

Regular practice and hands-on experience are essential for mastering fiber optic color codes. Technicians should have opportunities to work with real cables and connectors to reinforce their understanding of the color codes.

How It Works

Deeper Technical Explanations

Understanding how fiber optic cables are color-coded involves knowing the counting directions and examples of counting logic.

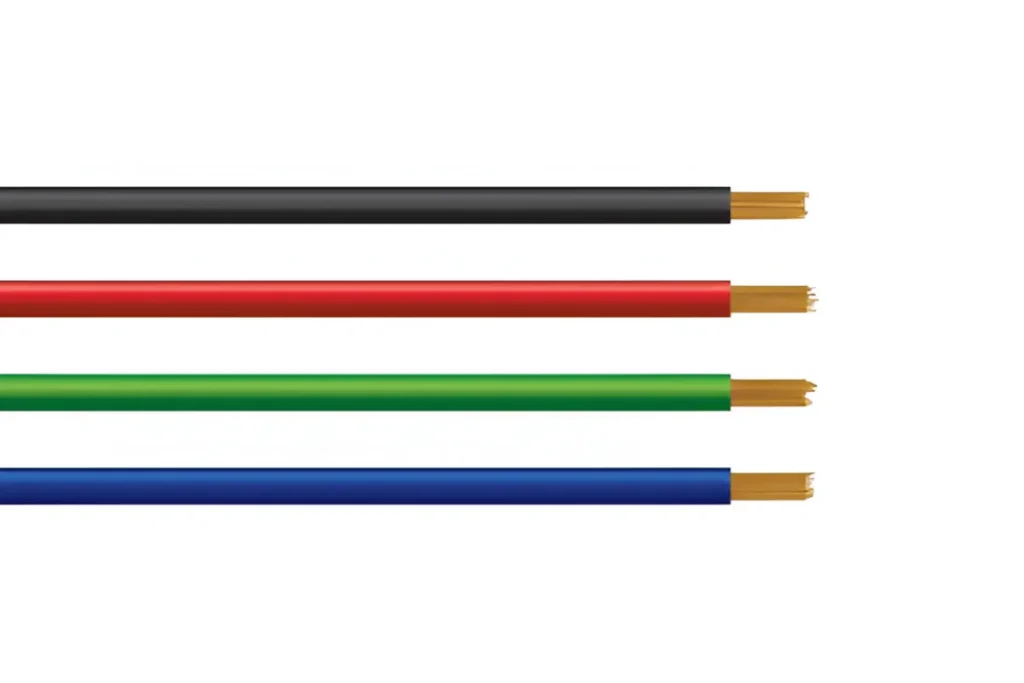

Counting Directions

In fiber optic cables, fibers are usually counted and organized in a specific order. For example, in a 12-fiber cable, the fibers are typically arranged in the following order: Blue, Orange, Green, Brown, Slate, White, Red, Black, Yellow, Violet, Rose, Aqua. This counting logic helps technicians accurately identify and connect fibers during installation and maintenance.

Examples of Counting Logic

When dealing with high-fiber-count cables, such as those with 144 or 288 fibers, the fibers are grouped into bundles of 12. Each bundle is then color-coded according to the standard order. For instance, in a 144-fiber cable, there would be 12 groups of 12 fibers, each group following the standard color order.

Adhering to fiber optic color codes is essential for efficient and reliable network operations. It simplifies installation, maintenance, and troubleshooting, ensuring accurate connections and reduced errors. By following standardized color codes and considering professional cabling solutions, you can ensure the long-term reliability and performance of your network.

FAQs

What are the 12 core colors of optical fiber?

The standard 12 fiber color code in order is:

- Blue

- Orange

- Green

- Brown

- Slate (Gray)

- White

- Red

- Black

- Yellow

- Violet

- Rose (Pink)

- Aqua

What is the color order of fiber optics?

The order follows the TIA-598C standard, ensuring consistency across all installations. For cables with more than 12 fibers, the colors repeat in groups of 12, often with a stripe or additional marking.

How to memorize the fiber color code?

A common mnemonic for memorizing the 12-color sequence is:

"Big Oranges Grow Best So Why Run Back Yard Vegetables Round Again."

Each first letter corresponds to the color in order:

- Blue, Orange, Green, Brown, Slate, White, Red, Black, Yellow, Violet, Rose, Aqua.

Using this phrase makes it easier to recall the sequence when working with fiber optics.